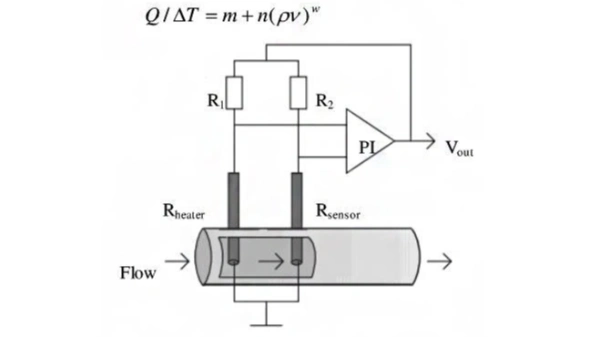

Working principle of Thermal gas mass flowmeter

Based on the heat conduction effect, the core components of Thermal gas mass flowmeter are heating elements and temperature sensors.

Gas flow carries away heat from heating elements, and the flow rate is positively correlated with heat loss and temperature changes.

By measuring temperature changes and algorithms, the gas mass flow rate can be directly calculated without temperature or pressure compensation.

Product advantages

High precision: Accurate measurement under complex working conditions with low error.

Wide range: can cover a small to large flow range, suitable for multiple scenarios.

High reliability: no moving parts, minimal mechanical wear, few malfunctions, long lifespan.

Fast response: Quickly capture traffic changes to meet real-time monitoring needs.

Application Fields

Chemical industry:

Measure the flow rate of raw material gas and process gas to optimize production processes.

Environmental protection field:

Monitor the flow of industrial waste gas and biogas emissions to assist in energy conservation and emission reduction.

Energy sector:

used for natural gas metering, fuel gas control in power plants, and ensuring energy utilization.

Electronics industry:

precise measurement of semiconductor manufacturing specialty gases, stable production processes.

Development Trends

Integrate with the Internet of Things and big data to achieve remote monitoring, intelligent diagnosis, and data analysis.

Optimize high temperature resistance, corrosion resistance, and explosion-proof performance for special needs, and expand application scope.