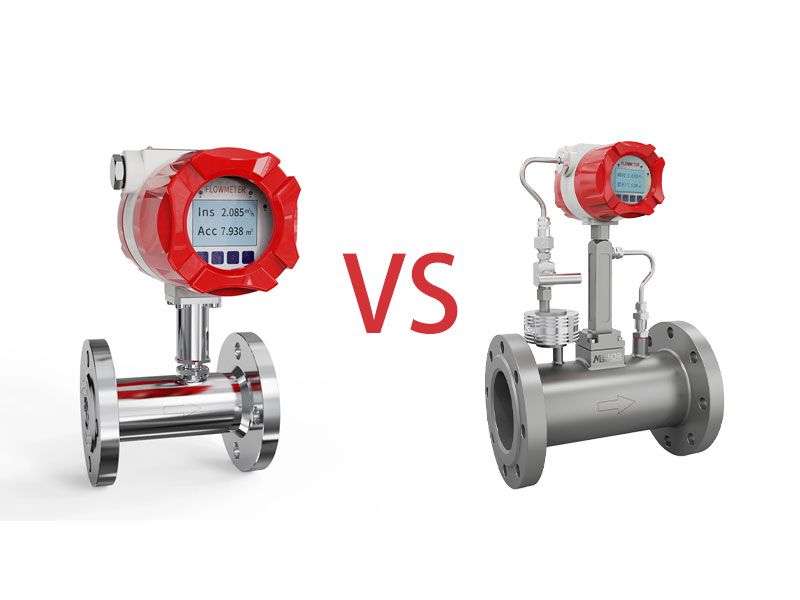

Turbine flowmeter and vortex flowmeter are two common flow measurement instruments, and their differences are as follows:

Working principle

Turbine flowmeter: It uses an impeller placed in the fluid to sense the average velocity of the fluid and derive the flow rate. When the measured fluid flows through the sensor, the impeller rotates under the action of the fluid, and its speed is proportional to the average flow velocity of the pipeline. The rotation of the impeller periodically changes the magnetic resistance value of the magneto electric converter, and the magnetic flux in the detection coil changes periodically, generating a periodic induced potential, that is, an electrical pulse signal. After amplification by an amplifier, it is sent to the display instrument for display.

Vortex flowmeter: based on the Karman vortex principle for flow measurement. When a fluid flows through a non streamlined object perpendicular to its flow direction (such as a vortex generator), two columns of asymmetric vortices are alternately generated on both sides downstream, and these two columns of vortices are arranged alternately and regularly, forming a Karman vortex street. The separation frequency of vortices is directly proportional to the flow velocity of the fluid. By detecting the frequency of vortices, the flow rate of the fluid can be calculated.

Structural characteristics

Turbine flowmeter: mainly composed of turbine sensors, preamplifiers, and display instruments. Turbine sensors include components such as impellers, shafts, bearings, and housings, which have relatively complex structures. Rotating components such as impellers may affect measurement accuracy due to wear and tear during long-term use.

Vortex flowmeter: usually composed of sensors and converters. The sensor part includes vortex generators, detection elements, etc. It has no rotating parts, a relatively simple structure, high reliability, and low maintenance.

Measurement accuracy

Turbine flowmeter: It has high accuracy, generally up to ± 0.2%~± 0.5%, and is widely used in high-precision measurement requirements. But with the increase of usage time and the influence of impurities in the fluid, the accuracy may decrease.

Vortex flowmeter: The accuracy is generally ± 1.0%~± 1.5%. Although the accuracy is slightly lower than that of turbine flowmeter, it can meet the measurement requirements in some industrial occasions where accuracy requirements are not extremely high. Its accuracy is relatively less affected by fluid properties and flow conditions.

Scope of application

Turbine flowmeter: suitable for measuring low viscosity, clean fluids such as gasoline, diesel, water, etc. For high viscosity fluids, due to their significant resistance to impeller rotation, it can affect measurement accuracy and is generally not suitable. Meanwhile, the impurity particles contained in the fluid are also prone to wear on the impeller and bearings, leading to increased measurement errors.

Vortex flowmeter: capable of measuring various fluids, including liquids, gases, and vapors. Not sensitive to changes in fluid viscosity, suitable for measuring high viscosity, low Reynolds number fluids. However, when measuring small flow rates, the measurement accuracy may be affected due to weak vortex signals.

Pressure loss

Turbine flowmeter: The pressure loss is relatively large because when the fluid flows through the turbine, it needs to push the impeller to rotate, which consumes some energy and leads to a pressure drop. In some systems that require high pressure loss, this factor needs to be considered.

Vortex flowmeter: The pressure loss is relatively small because it does not have rotating components like a turbine flowmeter that obstruct the fluid. The fluid flows smoothly through the sensor, and the pressure loss is mainly caused by local resistance caused by the vortex generator.

Output signal

Turbine flowmeter: The output is a pulse signal proportional to the flow rate, with a high signal frequency, which is convenient for remote transmission and interface with computers and other equipment. By counting and processing the pulse signal, the numerical value of the flow rate can be obtained.

Vortex flowmeter: It also outputs pulse signals, but its signal frequency is relatively low. The flow rate can also be measured by analyzing and processing the pulse signal. Some vortex flowmeters can also output analog signals, such as 4-20mA current signals, to meet the needs of different users.