In the field of industrial automation process control, precise measurement of fluid flow is crucial. Metal tube float flow meters, with their unique advantages, have become commonly used variable area flow measurement instruments and have demonstrated their skills in many industries.

1、 Working principle

The metal tube float flowmeter operates based on the principle of force balance. When the measured fluid flows through a vertical conical measuring tube from bottom to top, the float inside the tube will experience upward fluid buoyancy and downward gravity.

The greater the fluid flow rate, the greater the buoyancy on the float, and the float will rise inside the tube. When the buoyancy of the float is balanced with gravity, the float stabilizes at a certain height.

The height of the float corresponds to the fluid flow rate, and the position of the float is transmitted to the indicator outside the measuring tube through magnetic coupling and other methods, thereby displaying the fluid flow rate value.

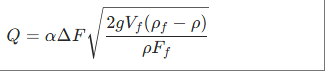

The basic equation for volumetric flow rate Q expressed in formula is:

In the formula, α is the flow coefficient of the instrument, which varies depending on the shape of the float;

Δ F is the circulating annular area;

G is the local gravitational acceleration;

V f is the volume of the float;

ρ f is the density of the float material;

ρ is the density of the measured fluid;

F f is the cross-section at the working diameter (maximum diameter) of the float.

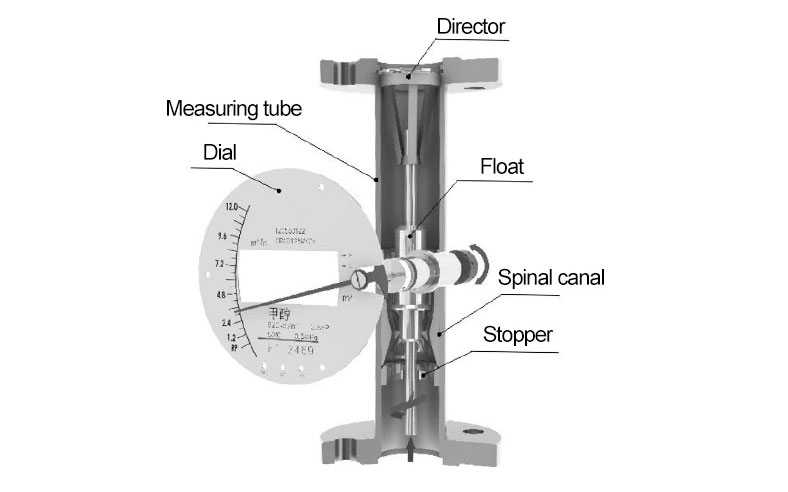

There is also a specific relationship between the circulating annular area and the height of the float. Under certain conditions, the height of the float inside the cone tube corresponds proportionally to the volumetric flow rate. By reading the float height and converting it into the corresponding volumetric flow scale through a converter, flow detection is completed.

2、 Structural analysis

Measurement tube:

mostly conical or cylindrical metal tubes, used as fluid flow channels, have high machining accuracy, good corrosion resistance and pressure resistance to ensure measurement accuracy and adapt to complex working conditions.

Float:

As the core measuring element, it is made of materials with a density greater than the measured fluid, such as stainless steel, copper alloy, etc.

For special media, there are also floats made of ceramics or surface coated with anti-corrosion materials. Floats come in various shapes, such as spherical, cylindrical, dumbbell shaped, etc., and different shapes are suitable for different flow ranges and fluid characteristics.

Magnetic coupling system:

composed of a magnet on the float and a magnetic sensor or indicator outside the measuring tube. By utilizing magnetic coupling, the position information of the float inside the measuring tube can be accurately transmitted, avoiding fluid leakage and facilitating remote transmission.

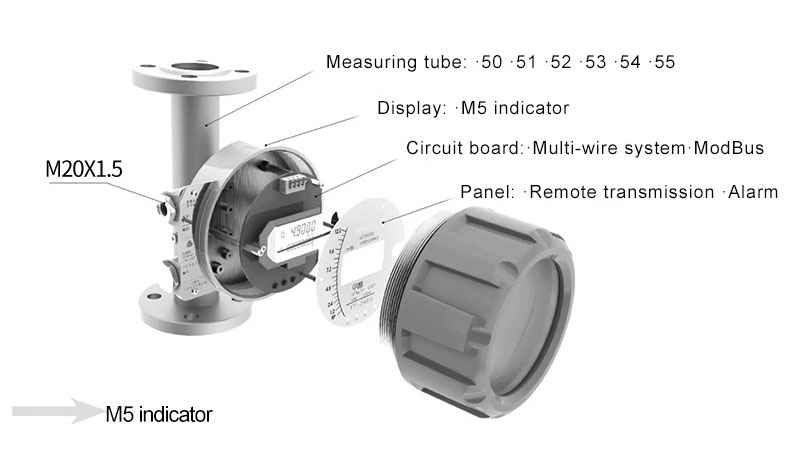

Indicator:

Used to display flow values, commonly in two ways: mechanical pointer display and electronic digital display. Advanced indicators also have multiple signal output functions, such as 4-20mA current signals, pulse signals, etc., which are convenient to connect with automation control systems and achieve remote monitoring and adjustment of flow.

3、 Performance advantages are fully demonstrated

Accuracy guarantee:

The general accuracy level can reach ± 1.0% – ± 2.5%, and products with special design and calibration have higher accuracy, which can meet the flow measurement accuracy requirements of most industrial scenarios.

Wide range measurement:

The flow measurement range is wide, with a range ratio of 10:1 or even higher, which can accurately measure large flow changes and adapt to fluid measurement of different flow scales.

Low pressure loss:

Especially under low flow conditions, the pressure loss is small and has a weak impact on the pressure of the pipeline system. It has obvious advantages in systems with high pressure requirements and can reduce energy loss.

High reliability:

simple structure, no complex moving parts inside, low failure rate, reliable operation. Low daily maintenance, long service life, able to operate stably in harsh industrial environments, reducing maintenance costs and downtime.

Quick response:

It can track fluid flow changes in a timely manner, provide real-time feedback on flow dynamics, and is of great significance for systems that require precise control and monitoring of flow. It is conducive to adjusting process parameters in a timely manner, ensuring production stability and product quality.

4、 Key points for selection control

Fluid characteristic considerations:

It is necessary to specify the type of fluid being tested (liquid, gas, or vapor), corrosiveness, viscosity, density, etc. For corrosive fluids, corrosion-resistant materials should be selected to make measuring tubes and floats; For high viscosity fluids, it is necessary to consider the shape of the float and the diameter of the flow meter to ensure measurement accuracy.

Adaptive flow range:

Determine the flow meter range based on the maximum and minimum flow rates of the fluid in the actual process, ensuring that the selected range covers the actual flow range, and the normal flow rate is within the range of 1/3-2/3 of the range to ensure measurement accuracy.

Adaptation to working conditions:

Understand the working pressure and temperature inside the pipeline, and select a flow meter that can withstand the corresponding conditions. The performance of measuring tubes and float materials will vary with temperature and pressure, and it is necessary to select them reasonably based on actual working conditions.

Accuracy requirement matching:

Determine the required accuracy based on process requirements and measurement purposes. If high precision is required, high-precision grade flow meters should be selected, and on-site or regular calibration should be considered.

Installation condition adaptation:

Consider installation location space, pipeline routing, and layout. Metal tube float flow meters generally need to be installed vertically, with fluid passing from bottom to top and a certain length of straight pipe section in front and behind to ensure stable fluid flow and improve measurement accuracy.

5、 Diversified application areas

Chemical industry:

used for flow measurement of various chemical raw materials, intermediates, and products, such as acids, bases, salt solutions, organic solutions, etc. Its corrosion resistance and high-precision measurement capability are in line with the diverse and corrosive characteristics of fluids in chemical production.

Oil and gas industry:

used to measure the flow of crude oil, refined oil, natural gas, etc. in oil extraction, refining, and natural gas transportation. High voltage resistance and anti vibration characteristics enable it to adapt to harsh working environments in the industry.

Water treatment industry:

It can measure various fluid flow rates in industrial water, domestic water, and sewage treatment processes, such as raw water, clean water, sewage, chemicals, etc., which is crucial for monitoring and controlling the operation and cost of water treatment systems.

Pharmaceutical industry:

In pharmaceutical production, precise measurement and control of various drug solutions, solvents, and gas flow rates are carried out to ensure drug quality and stability. Its hygienic design and high-precision measurement meet the strict requirements of the pharmaceutical industry.

Food and beverage industry:

measuring fluid flow in food processing, such as milk, juice, syrup, water, etc. Good corrosion resistance and hygiene performance, in line with industry hygiene standards, ensuring product quality and safety.

The metal tube float flowmeter occupies an important position in industrial flow measurement due to its unique measurement principle, reasonable structural design, excellent performance advantages, clear selection points, and wide application fields, providing key support for precise control and efficient operation of production processes in various industries.