1.Highlight performance advantages

Accurate continuous measurement:

The non-contact measurement method makes the probe non-contact with the surface of the medium, greatly reducing the errors and interference caused by physical contact. It can quickly and stably measure the liquid level of media with different characteristics, whether it is liquid, slurry or granular materials, almost unaffected by external factors such as temperature, pressure, gas composition, etc., and always provide accurate and reliable liquid level data. For example, in crude oil storage tanks in the petrochemical industry, even if there are significant changes in environmental temperature and pressure, radar level gauges can stably measure the liquid level.

Strong anti-interference ability:

In complex industrial environments, interference echoes often affect the accuracy of liquid level measurement. The radar level gauge, with advanced microprocessing technology and professional debugging software, has powerful interference echo suppression function. Faced with false echoes under complex working conditions, it can deeply analyze signals, accurately identify level echoes, and ensure accurate liquid level measurement. For example, in chemical reaction vessels with frequent stirring, although there is a lot of interference, radar level gauges can still accurately measure the liquid level.

Safety and energy conservation:

In terms of material selection, the radar level gauge adopts materials with high chemical and mechanical stability, which can work stably in harsh chemical environments for a long time, and can be recycled and reused after the end of its service life, meeting the requirements of environmental protection and sustainable development, ensuring production safety and achieving efficient resource utilization. High reliability and low maintenance requirements:

Microwave propagation is almost unaffected by external environmental interference, and radar level gauges do not come into direct contact with measuring media, making them widely applicable in various complex situations. It is capable of measuring liquid levels in high vacuum environments and monitoring material heights in dusty silos. At the same time, high-quality materials and advanced manufacturing processes make it durable under complex chemical and physical conditions, providing accurate level signals for a long time and reducing equipment maintenance frequency and costs. For example, in the ore bin of a mine, even in harsh environments, radar level gauges can work stably for a long time.

Easy to maintain and operate:

To reduce the threshold for use and maintenance difficulty, the radar level gauge is equipped with comprehensive fault alarm and self diagnostic functions. When the device encounters an abnormality, the operation display module quickly pops up an error code, and the user quickly analyzes the cause of the fault according to the prompt, promptly eliminates the fault, and ensures the normal operation of the instrument.

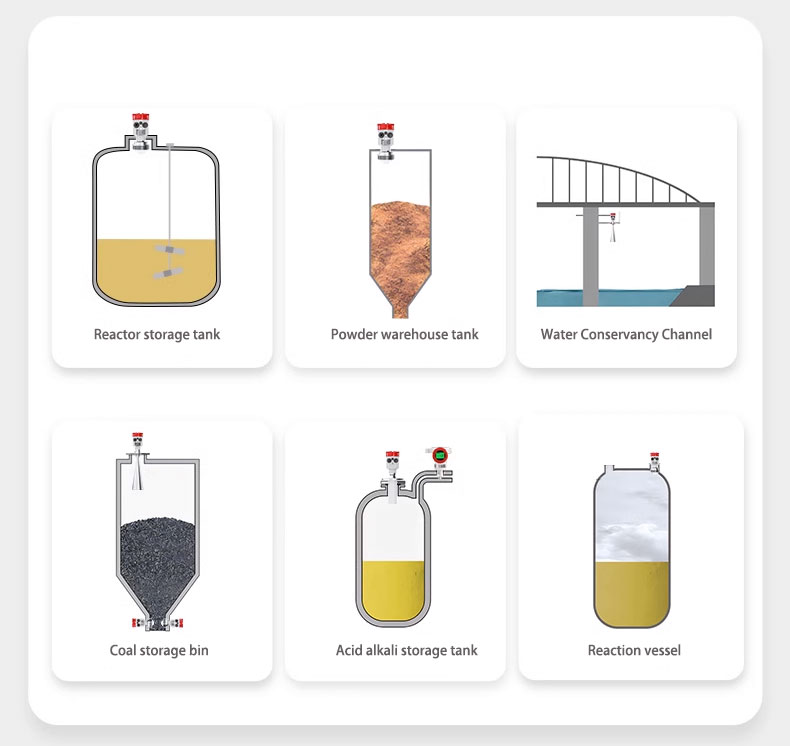

Widely applicable scope:

From the shape of the tank body, whether it is a spherical tank, horizontal tank, cylindrical tank, or cylindrical cone tank, the radar level gauge can accurately measure the liquid level; From the perspective of tank function and usage, it is capable of monitoring liquid levels in storage tanks for raw materials, buffer tanks, as well as special pipelines such as microwave tubes and bypass tubes; From the type of medium being tested, whether it is liquid, granular material, or slurry, radar level gauges can accurately sense changes in liquid level.

2.Diversified application areas

Petrochemical industry:

Widely used in various chemical equipment, storage tanks, and storage tanks to accurately measure the liquid level and density of chemical raw materials and finished products, monitor material storage capacity and input/output in real time, and provide key data support for stable production operation. During the storage and transportation of crude oil, by accurately measuring the liquid level of crude oil in the storage tank, inventory can be accurately controlled and trade handover can be carried out; For the level measurement of corrosive liquids such as acid, alkali, salt, etc. in various chemical raw material storage tanks, radar level gauges, due to their non-contact measurement characteristics, avoid direct contact with the measured medium, prevent corrosion and wear of the instrument, and ensure the accuracy of measurement and the service life of the instrument.

Food processing industry:

Can strictly monitor and accurately control the liquid level of food storage tanks and conveying pipelines, ensure food quality and safety, and avoid product quality problems caused by abnormal liquid levels. During the beverage production process, monitor the liquid level of various beverage storage tanks to achieve automated production and precise ingredient preparation; For the storage and filling process of edible oil, real-time monitoring of the liquid level of the oil tank provides accurate liquid level data for the production, storage, and sales of edible oil, which helps enterprises to arrange production and inventory management reasonably.

Water treatment industry:

Whether it is large water storage tanks in urban water supply systems, or reaction tanks and sedimentation tanks in sewage treatment plants, radar level gauges can accurately measure water levels, providing a basis for the rational utilization of water resources and efficient operation of sewage treatment. In the process of sewage treatment, it can be used to measure the liquid level of sludge and water in the sedimentation tank, helping operators control the operating parameters of the sedimentation tank, such as sludge discharge time and discharge volume, to ensure the effectiveness of sewage treatment; For the measurement of liquid level in clean water tanks, it can accurately and real-time reflect changes in water level, provide accurate liquid level information for the scheduling and management of water supply systems, and ensure the stability and safety of urban water supply.

Other industries:

In the pharmaceutical industry, meeting the strict requirements of pharmaceutical factories for hygiene, precision, and reliability, ensuring accurate measurement and quality control of materials in the drug production process; In agriculture, it can be used to monitor the water level of agricultural ponds and small reservoirs to ensure water supply for agricultural production; It also plays an important role in industries such as textiles, papermaking, printing, and automobile manufacturing.

In the construction of smart cities, real-time monitoring of urban water resource usage and consumption provides scientific basis for water resource management; In the field of intelligent manufacturing, precise control of material and raw material liquid levels on the production line achieves production automation and intelligence; In the field of smart homes, some household appliances such as washing machines and water heaters also use radar level gauges to monitor water levels, providing users with a convenient and intelligent home living experience.