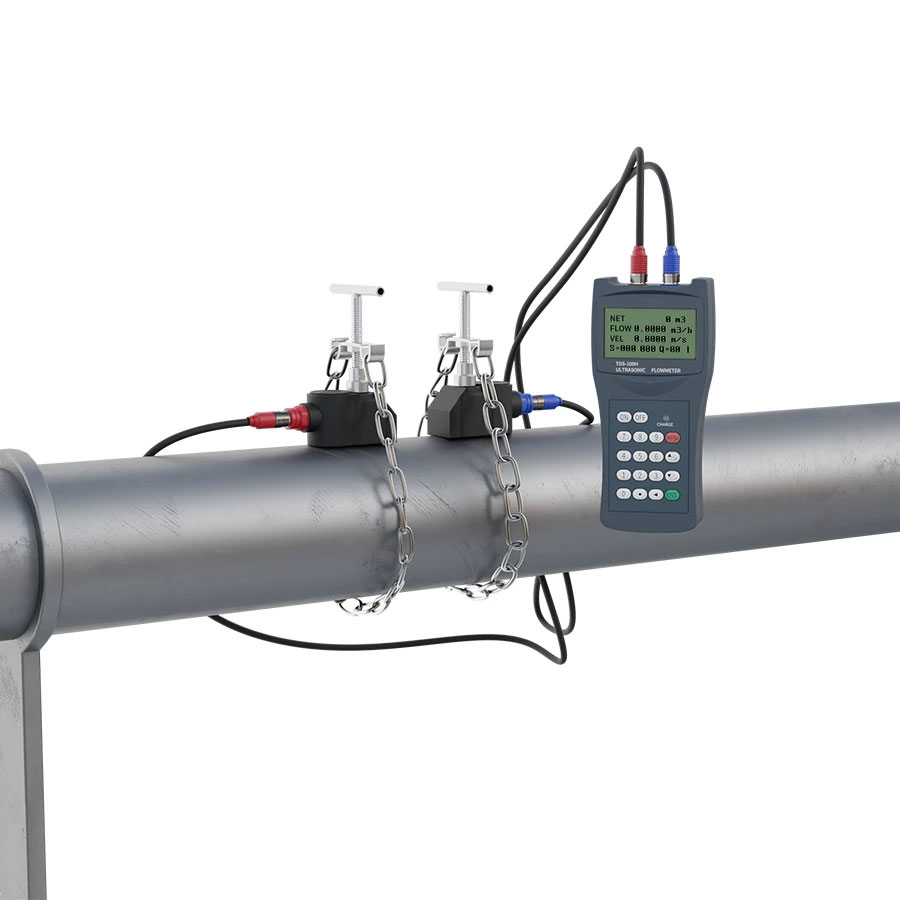

Handheld ultrasonic flowmeter, as an advanced flow measurement instrument, has become a powerful tool for flow detection in many industries due to its unique technological advantages and convenient usage.

1、 Working principle

Handheld ultrasonic flow meters are mainly based on the propagation characteristics of ultrasonic waves in fluids to achieve flow measurement, and there are two common principles.

(1) Time difference method

This is the most commonly used measurement principle. When ultrasound propagates in a fluid, the speed of forward propagation (in the same direction as the fluid flow) increases, while the speed of backward propagation (opposite to the fluid flow direction) decreases.

Through a pair of ultrasonic probes, one probe emits ultrasonic waves and the other probe receives them.

By measuring the time difference between the propagation of ultrasonic waves in both forward and reverse directions, and utilizing this time difference in relation to the specific relationship between fluid velocity, the fluid velocity can be calculated.

For example, when measuring the flow rate of a tap water pipeline, by accurately measuring the time difference of ultrasonic propagation, the water flow velocity and flow rate can be accurately calculated based on the above formula.

(2) Doppler method

When the fluid contains scatterers such as particles, bubbles, or suspended solids, the Doppler method is suitable. By measuring the frequency shift, the fluid flow velocity can be calculated, and then combined with the pipeline cross-sectional area to obtain the flow rate.

When measuring sewage flow in sewage treatment plants, handheld ultrasonic flow meters using the Doppler method can effectively complete the measurement task due to the presence of various impurities in the sewage.

2、 Product Features

(1) Excellent portability

Handheld ultrasonic flow meters are small in size and light in weight, usually designed as handheld boxes or shapes that are easy to hold, making it convenient for operators to carry them to different measurement sites.

Whether in every corner of the factory workshop or in outdoor work points of the municipal pipeline network, it can be easily brought to the location where measurement is needed and flow detection work can be carried out at any time.

(2) Non contact measurement (external clamp type)

The external clamp type handheld ultrasonic flowmeter only requires the probe to be clamped on the outer wall of the pipeline, without any damage or drilling to the pipeline, nor does it need to come into contact with the fluid inside the pipeline.

This feature makes it significantly advantageous in measuring fluids with hazardous characteristics such as corrosiveness, toxicity, or high temperature and pressure, avoiding direct contact between operators and hazardous media, ensuring personnel safety, and not causing damage to pipelines or affecting their normal operation.

For example, when measuring the flow rate of corrosive chemical raw material pipelines in chemical enterprises, external clamp type handheld ultrasonic flow meters can show off their skills.

(3) High precision measurement

Generally speaking, the measurement accuracy of handheld ultrasonic flow meters is relatively high. The instrument accuracy using the time difference method can reach within ± 1%, while the accuracy using the Doppler method is usually within ± 2% – ± 5%.

At the same time, it also has good linearity and repeatability, with linearity better than 0.5% and repeatability accuracy better than 0.3%, which can provide reliable data for flow measurement. In some industries such as pharmaceuticals, food and beverage that require high flow accuracy, such high-precision measurement performance can meet strict production process requirements.

(4) Wide measurement range

The measurable range of pipe diameters is extremely wide, suitable for pipes ranging from small diameters (such as DN15mm) to ultra large diameters (DN6000mm). Simply select the appropriate sensor model based on the pipe diameter size.

Moreover, the types of fluids that can be measured are diverse, including but not limited to water, seawater, various oils, chemical solutions, industrial wastewater, and almost all acoustic fluids.

As long as the volume content of bubbles or solid particles in the fluid meets certain requirements (such as<10%), accurate measurement can be made. Whether it is large-diameter water pipelines in urban water supply systems or various small-diameter process pipelines in factories, handheld ultrasonic flow meters are capable of measuring flow rates.

(5) Easy to operate

Usually equipped with a fully Chinese human-machine interface, the operation menu is concise and clear, even non professional technicians can quickly get started. The installation process is also extremely simple.

Taking the installation of a common external clamp probe as an example, all that is needed is to set the pipeline parameters (such as pipeline material, diameter, wall thickness, etc.) in the host, apply coupling agent at a suitable position on the outer wall of the pipeline, install and fix the probe in the specified way (such as V method for smaller pipe diameters and Z method for larger pipe diameters), and then start measuring. When conducting temporary flow testing on site, operators can complete equipment installation and measurement operations in a short period of time.

(6) Rich functionality

In addition to real-time display of basic parameters such as flow rate and velocity, many handheld ultrasonic flow meters also have data storage functions, which can store measurement data for easy viewing and analysis in the future. The storage capacity can generally reach thousands or even more data.

Some models also come with a thickness measurement function, which can measure the wall thickness of pipelines and evaluate their corrosion status. And it supports multiple communication interfaces, such as RS232, RS485, etc., making it easy to connect with computers, data acquisition systems, and other devices to achieve remote transmission and sharing of data.

In the automation production management of some large industrial enterprises, flow meter data can be connected to the enterprise’s control system through communication interfaces to achieve real-time monitoring and management of flow data during the production process.

3、 Application Fields

(1) Industrial production

Chemical industry: In the process of chemical production, it is necessary to accurately measure the flow rate of various corrosive raw materials, intermediate products, and finished products.

The non-contact measurement characteristics of handheld ultrasonic flow meters enable them to safely and accurately measure the flow rate of highly corrosive liquids such as sulfuric acid and hydrochloric acid, providing data support for precise control and cost accounting in chemical production processes.

The oil and gas industry: from crude oil extraction and transportation to refining and chemical product production, flow measurement is indispensable in every link. In the inspection and maintenance of oil and natural gas pipelines, handheld ultrasonic flow meters can easily detect pipeline flow, timely detect pipeline leaks, blockages, and other issues, ensuring the safety and stability of energy transmission.

Electric power industry: used to measure the flow rate of circulating water, condensate water, chemical reagents and other fluids in power plants. For example, in thermal power plants, accurately measuring the circulating water volume of the steam turbine can help optimize the operating efficiency of the unit and reduce energy consumption; In nuclear power plants, measuring coolant flow is crucial for ensuring the safe operation of nuclear reactors, and handheld ultrasonic flow meters can meet the temporary or regular flow detection needs in these situations.

Metallurgical industry: In the smelting process of steel, non-ferrous metals, etc., strict flow control requirements are imposed on fluids such as cooling water, oxygen, and gas. Handheld ultrasonic flow meters can be used for on-site flow measurement and calibration, ensuring stable supply of various fluids during the production process, improving product quality and production efficiency.

(2) Municipal Engineering

Urban water supply and drainage: In urban water supply systems, it can be used to detect the flow of water supply pipelines, evaluate the operation status of the water supply system, timely detect pipeline leakage points, and reduce water resource waste.

In sewage treatment plants, it is possible to measure the flow rate of incoming sewage, treated effluent, and various treatment units within the plant, providing a basis for optimizing and managing the operation of sewage treatment processes.

Heating and Heating: In a centralized heating system, by measuring the hot water flow rate in the heating pipeline and combining it with the supply and return water temperature, the heating amount can be calculated, achieving monitoring and adjustment of the heating effect, ensuring the heating quality of residents, and also helping heating enterprises to carry out energy management and cost accounting.

(3) Scientific research

Handheld ultrasonic flow meters also play an important role in scientific research fields such as water conservancy, environmental science, and biomedicine. In water conservancy research, it can be used to measure the flow velocity and volume of water bodies such as rivers, channels, lakes, etc., providing data for water resource research, hydrodynamic model construction, etc;

In environmental science research, the discharge flow of industrial wastewater, rainwater, and other pollutants can be monitored to assess the environmental pollution situation; In biomedical experiments, it is possible to simulate blood flow in human blood vessels, measure the flow rate of relevant fluid models, and assist medical research.

4、 Limitations

Despite the numerous advantages of handheld ultrasonic flow meters, there are also some limitations. For example, for fluids with high gas content or a large amount of large particle impurities, measurement accuracy may be greatly affected, and even cannot be accurately measured.

When using an external clamp probe, factors such as the material, wall thickness, surface roughness, and lining inside the pipeline may interfere with the propagation of ultrasonic signals, thereby affecting the accuracy of measurement results.

In addition, the price of handheld ultrasonic flow meters is relatively high, which may cause concerns about procurement costs for some small businesses or projects with limited budgets.

Handheld ultrasonic flow meters have been widely used in many fields due to their unique working principle and excellent product characteristics, bringing great convenience to flow measurement work. With the continuous advancement and innovation of technology, its performance will continue to improve and its application scope will be further expanded, which will play a more important role in the field of traffic measurement in the future.

In practical use, users should choose and use handheld ultrasonic flow meters reasonably according to their specific measurement needs and site conditions, in order to fully leverage their advantages and ensure accurate and efficient flow measurement work.