In the complex process of industrial production, the accuracy of liquid level measurement directly affects production efficiency and safety. Guided wave radar level gauge, with its advanced working principle, has become the core equipment for precise measurement.

How can it stably obtain liquid level data under various complex working conditions? The following will elaborate on its working principle and technical advantages in detail.

1、 Measurement Basis Based on Time Domain Reflectance (TDR)

Signal generation and transmission:

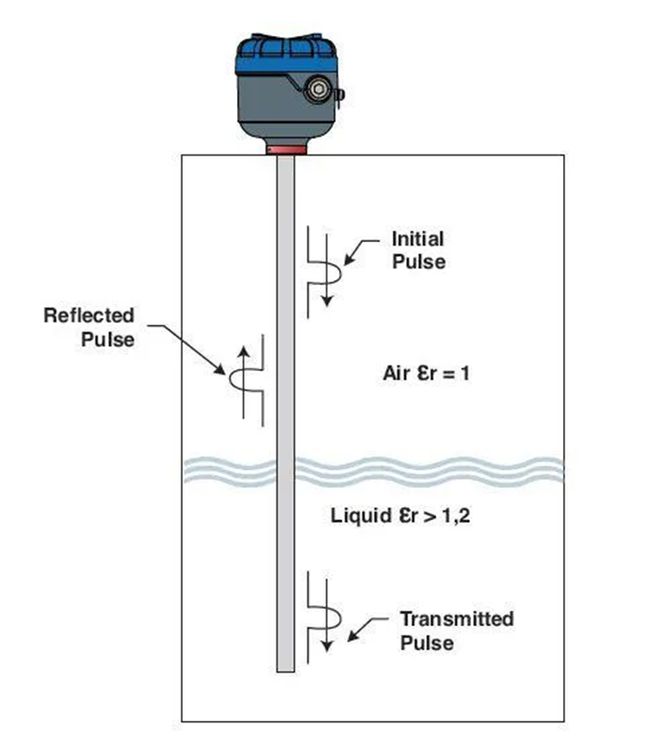

The internal signal generator of the instrument generates high-frequency pulse electromagnetic waves, which are coupled to a waveguide rod or cable through an antenna.

The waveguide rod/cable acts as an “electromagnetic wave highway”, guiding electromagnetic waves to propagate along specific paths and avoiding signal attenuation or interference due to spatial scattering.

Reflection principle:

When electromagnetic waves propagate to the surface of a medium, due to the significant difference in dielectric constant between the medium and air (such as the difference in dielectric constant between common liquids and air, which can reach tens of times), some energy is reflected, forming echoes and returning to the instrument receiving end in the opposite direction along the waveguide rod/cable.

2、 Accurate calculation of liquid level height

Time difference recording:

The instrument is equipped with a high-precision timing device, which accurately captures the time difference between the emission of electromagnetic waves and the reception of reflected echoes.

Formula calculation:

According to the principles of physics, given the propagation speed of electromagnetic waves (approximately the speed of light), the liquid level height is calculated using the formula “liquid level height=(propagation speed x time difference) ÷ 2”. Dividing by 2 is because electromagnetic waves need to go through the round-trip process of emission and reflection, and the calculation process is automatically completed by a microprocessor.

3、 Technical guarantee for anti-interference characteristics

Fixed propagation path:

The waveguide rod/cable limits the propagation trajectory of electromagnetic waves. In complex environments such as steam and mist, it is less likely to fail due to signal scattering compared to optical or ultrasonic measuring instruments.

Environmental factor immunity:

Changes in medium density, temperature, and pressure do not affect the difference in dielectric constant, so they do not interfere with the generation and measurement of reflected echoes, ensuring stable and reliable measurement results.

4、 Optimization and Expansion of Principle Applications

Low dielectric constant medium adaptation:

For low dielectric constant media, by increasing the transmission power and optimizing the signal processing algorithm, the reflected signal strength is improved to ensure measurement accuracy.

Special working condition protection:

using special material waveguide rods/cables to deal with corrosive media, ensuring the safe operation of equipment; Some high-end models support multi echo analysis, which can distinguish between real liquid level echoes and false echoes caused by obstacles inside the container, further improving measurement accuracy.

5、Summarize

The guided wave radar level gauge integrates advanced electromagnetic wave theory and precision signal processing technology, reflecting scientificity and reliability in all aspects from signal transmission, reflection to data calculation.

Based on this principle, it is widely used in various fields such as petrochemicals, food and pharmaceuticals, and wastewater treatment, providing a solid guarantee for accurate measurement in industrial production.

With the development of technology, its principle applications will continue to be optimized to meet the needs of more complex measurement scenarios.