Turbine flowmeter is a precision flow measurement instrument. When installing Mejor turbine flowmeter, the following precautions should be taken:

Installation location of Mejor turbine flowmeter

Requirements for straight pipe section: In order to ensure measurement accuracy, the turbine flowmeter should be installed on the straight pipe section, with a certain length of straight pipe section upstream and downstream. Generally speaking, the length of the upstream straight pipe section is not less than 10 times the pipe diameter, and the length of the downstream straight pipe section is not less than 5 times the pipe diameter.

Avoid vibration: Keep away from vibration sources such as large motors, compressors, pumps, and other equipment. Because vibration may cause damage to internal components of the flowmeter, affecting measurement accuracy. If vibration cannot be avoided, effective vibration reduction measures should be taken, such as installing vibration reduction brackets and using flexible connections.

Preventing electromagnetic interference: It should be avoided to install near strong electromagnetic fields, such as transformers, frequency converters, and other equipment. Because strong electromagnetic fields may interfere with the signal transmission of flow meters, resulting in measurement errors.

Easy to maintain: The installation location should be convenient for operators to perform daily maintenance, inspection, and calibration, and there should be sufficient space around it.

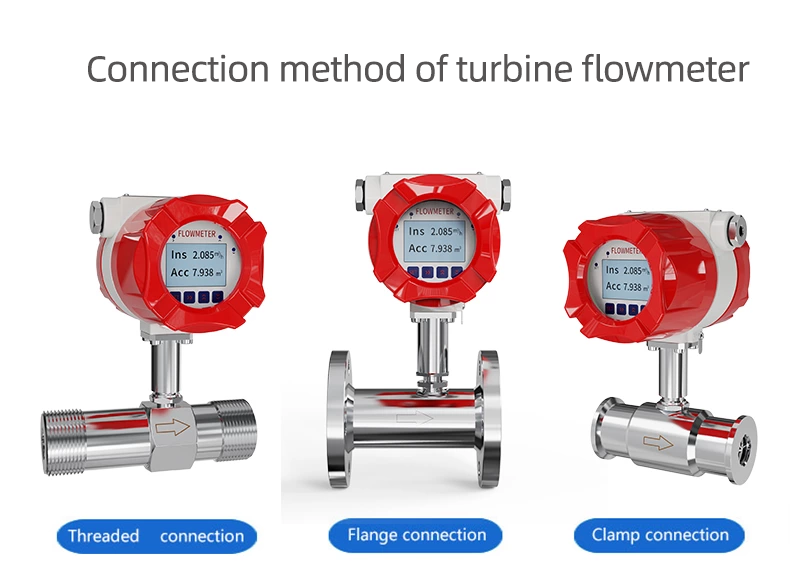

Mejor turbine flowmeter pipeline connection

Connection method: There are various connection methods for turbine flow meters, such as flange connection, threaded connection, etc. During installation, the appropriate connection method should be selected based on the material, pressure, flow rate, and other parameters of the pipeline, and ensure that the connection is firm, well sealed, and there should be no leakage.

Concentric installation: The axis of the flowmeter should be concentric with the axis of the pipeline to avoid eccentric installation. Otherwise, it will cause uneven flow of fluid in the pipeline, affecting measurement accuracy.

Avoid stress transmission: During installation, stress transmission from the pipeline to the flow meter should be avoided. For example, stress caused by thermal expansion, contraction, or improper installation of pipelines may cause deformation of flow meters, affecting measurement accuracy. Appropriate pipeline support and compensation measures can be adopted to eliminate stress.

Fluid conditions of Mejor turbine flowmeter

Fluid cleanliness: The tested fluid should be kept clean, free of impurities, particles, fibers, etc. Otherwise, these impurities may wear down the impeller of the flowmeter or clog the sensor, affecting measurement accuracy and service life. Therefore, a suitable filter should be installed upstream of the flowmeter, and its filtration accuracy should be determined based on the properties of the fluid and the requirements of the flowmeter.

Prevent cavitation: Ensure that the fluid pressure is within an appropriate range to avoid cavitation. Cavitation can increase the measurement error of the flowmeter and even damage it. In the selection of installation location, it is necessary to ensure that the pressure at the inlet of the flowmeter is high enough to prevent the formation of bubbles in the fluid during the flow process.

Fluid temperature: Note that the temperature of the measured fluid should not exceed the operating temperature range of the flowmeter. Excessively high or low temperatures can affect the performance and lifespan of flow meters. If the fluid temperature exceeds the range, corresponding cooling or heating measures should be taken to ensure that the fluid temperature is within the appropriate range.

Electrical connection

Correct wiring: Follow the instructions of the flowmeter to connect the power lines, signal lines, etc. correctly, ensuring that they are firmly connected, in good contact, and there is no looseness or short circuit.

Good grounding: In order to ensure the normal operation and safety of the flowmeter, it should be ensured that it is well grounded. The grounding resistance should meet the requirements of relevant standards, generally not exceeding 10 Ω. Good grounding can effectively prevent electromagnetic interference and static electricity accumulation, protecting the safety of flow meters and operators.

Before installing the Mejor turbine flowmeter, it is necessary to carefully read the installation instructions provided by the manufacturer and strictly follow the requirements for installation. After installation, debugging and calibration are still required to ensure that the flowmeter can work accurately and reliably.