*We respect your confidentiality and all information are protected.

Choose Your Competitive Product, Now!

Compared with most of other suppliers, we only focus on making good instruments with competitive barriers, strict quality control, and true high precision.

*We respect your confidentiality and all information are protected.

Are You A Factory and Need to Purchase Instruments for Your Equipment?

*We respect your confidentiality and all information are protected.

Are You A Wholesaler, Agent And Distributor?

*We respect your confidentiality and all information are protected.

Are You A Wholesaler, Agent And Distributor?

*We respect your confidentiality and all information are protected.

Are You an Instruments Seller in the local market and want to build your brand?

*We respect your confidentiality and all information are protected.

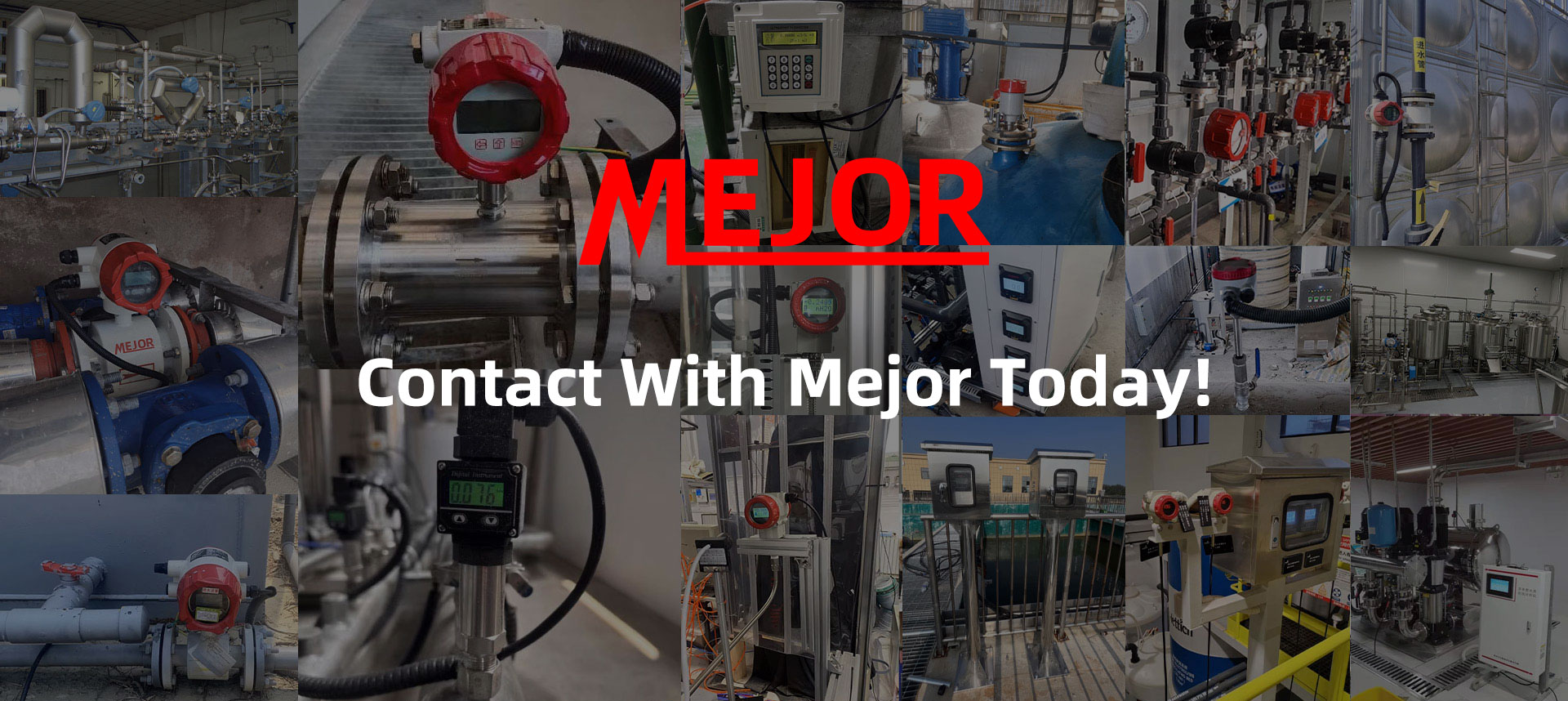

Why Choose Mejor?

Mejor is committed to quality across all aspects of our business – our people, processes and products. We call this ‘the Mejor standard’.

Our Capabilities

Expert Craftsmanship

We don’t just make instruments, we craft precision. Our experienced team provide you good products with high precision, strong adaptability, quick response, low maintenance cost.

Custom Solutions

Your project is unique, so your instruments should be too. Share your needs, and we’ll design instruments and provide blueprints that fit the bill perfectly.

Reliable and Fast Delivery

When we say you’ll have your instruments on time, we mean it. Our efficient production lines and expert logistics ensure you get what you need, when you need it.

*We respect your confidentiality and all information are protected.

Valuable Partner