In the realm of fluid measurement, the Coriolis Mass Flowmeter stands out as a highly accurate and versatile instrument. Named after the French mathematician and engineer Gaspard-Gustave de Coriolis, who first described the underlying physical principle in the 19th century, this flowmeter has revolutionized the way industries measure and manage fluid flows.

1.How It Works:

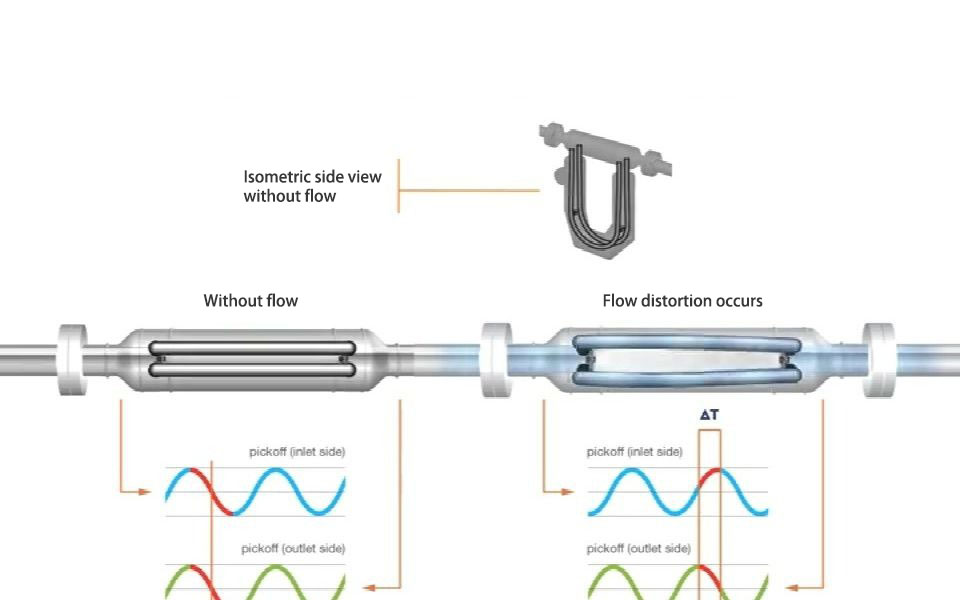

The operation of a Coriolis Mass Flowmeter is based on the Coriolis effect. When a fluid flows through a vibrating tube, the movement of the fluid relative to the vibrating tube generates a Coriolis force.

This force causes a twist or phase shift in the vibrating tube, which is directly proportional to the mass flow rate of the fluid.

The flowmeter consists of a sensor unit with one or more vibrating tubes, typically made of stainless steel or other corrosion-resistant materials. An actuator, such as an electromagnetic driver, sets the tubes into vibration at their natural frequency. As the fluid enters the vibrating tubes, the Coriolis force acts on it, causing the tubes to twist.

Sensors, usually located at the inlet and outlet of the tubes, detect the resulting phase shift or time delay between the vibrations at these two points.

This phase shift is then converted into an electrical signal, which is processed by a transmitter to provide an accurate measurement of the mass flow rate.

In addition to measuring mass flow, many Coriolis Mass Flowmeters can also determine the density of the fluid. The frequency of vibration of the tubes is influenced by the mass of the fluid inside them.

By measuring the change in vibration frequency, the flowmeter can calculate the fluid density. Some models are even capable of measuring other parameters such as temperature and viscosity, providing a comprehensive set of data for process control and optimization.

2.Key Advantages:

Exceptional Accuracy

Coriolis Mass Flowmeters are renowned for their high measurement accuracy, often achieving accuracies of ±0.1% to ±0.2% of the measured value. This level of precision makes them ideal for applications where exact flow measurement is crucial, such as in chemical reactions, pharmaceutical manufacturing, and custody transfer of valuable fluids.

Unlike other types of flowmeters that may be affected by factors like fluid viscosity, density changes, or flow profile, Coriolis meters directly measure mass flow, providing consistent and reliable results regardless of these variables.

Wide Range of Fluid Compatibility

These flowmeters can handle a diverse range of fluids, including liquids, gases, slurries, and even two-phase mixtures.

Whether it’s a highly viscous liquid, a gas with varying density, or a fluid containing solid particles, a Coriolis Mass Flowmeter can accurately measure the mass flow rate. This versatility makes them suitable for use in various industries, from oil and gas production to food and beverage processing.

No Moving Parts in the Flow Path

One of the significant advantages of Coriolis Mass Flowmeters is the absence of moving parts within the fluid flow path. This design feature eliminates the risk of wear and tear due to mechanical components interacting with the fluid, reducing the need for frequent maintenance and replacement.

As a result, these flowmeters have a longer service life and higher reliability compared to some other types of flow measurement devices.

The lack of internal obstructions also means that the flowmeter has a low pressure drop, minimizing the energy required to pump the fluid through the system.

Multiple Parameter Measurement

As mentioned earlier, many Coriolis Mass Flowmeters are capable of measuring not only mass flow but also density, temperature, and in some cases, viscosity. This multi-parameter measurement capability provides valuable information for process monitoring and control. For example, in a chemical manufacturing process, knowing the density and mass flow rate of the reactants can help ensure accurate formulation and reaction control. In a food and beverage production line, measuring the density of the product can be an indicator of quality and consistency.

3.Applications Across Industries:

Oil and Gas

In the oil and gas industry, Coriolis Mass Flowmeters play a crucial role in various applications. They are used for accurate measurement of crude oil, refined products, and natural gas during production, transportation, and storage. In oil pipelines, these flowmeters help in monitoring the flow rate of oil, ensuring efficient distribution and preventing over or under supply.

During gas processing, they enable precise measurement of gas flow, which is essential for proper separation, treatment, and metering for sales. In offshore oil platforms, where space and reliability are critical, the compact design and high accuracy of Coriolis Mass Flowmeters make them an ideal choice for flow measurement.

Chemical and Petrochemical

Chemical and petrochemical plants rely on Coriolis Mass Flowmeters for precise control of raw materials and products. In chemical reactions, accurate measurement of reactant flow rates is essential to ensure consistent product quality and yield. These flowmeters can handle a wide range of chemicals, including corrosive and high-temperature fluids.

They are also used in the blending of different chemicals to achieve the desired product specifications. In petrochemical refineries, Coriolis Mass Flowmeters are used to measure the flow of hydrocarbons, helping to optimize the refining process and improve overall plant efficiency.

Pharmaceutical

The pharmaceutical industry demands the highest level of accuracy and reliability in fluid measurement for drug manufacturing. Coriolis Mass Flowmeters are used to precisely measure the flow of active pharmaceutical ingredients (APIs), solvents, and other critical fluids during the production process.

The ability to measure multiple parameters, such as density and temperature, is particularly valuable in pharmaceutical manufacturing, as these factors can affect the quality and efficacy of the final product. The absence of moving parts in the flow path also helps to maintain a sterile environment, reducing the risk of contamination.

Food and Beverage

In the food and beverage industry, Coriolis Mass Flowmeters are used for accurate measurement of ingredients during production.

Whether it’s measuring the flow of sugar syrup in a beverage plant, the addition of flavorings in a food manufacturing process, or the dosing of water in a brewing operation, these flowmeters ensure consistent product quality and taste.

They are also used for monitoring and controlling the flow of cleaning and sanitizing agents, which is crucial for maintaining hygiene standards in food and beverage production facilities.

Water and Wastewater Treatment

Coriolis Mass Flowmeters are used in water and wastewater treatment plants to measure the flow of water, chemicals, and sludge. In water treatment, they help in accurately dosing chemicals such as coagulants and disinfectants, ensuring the proper treatment of water for consumption.

In wastewater treatment, these flowmeters are used to monitor the flow of influent and effluent, as well as the transfer of sludge between different treatment processes. Their ability to measure in harsh environments, including those with high solids content, makes them suitable for use in wastewater treatment applications.

4.Considerations and Limitations:

Despite their many advantages, Coriolis Mass Flowmeters do have some limitations. They can be relatively expensive compared to other types of flowmeters, especially for larger pipe sizes. Their accuracy can be affected by external vibrations, so proper installation and isolation from sources of vibration are necessary.

Additionally, they may not be suitable for measuring very low-density gases or fluids with extremely high gas content, as the Coriolis force generated may be too small to accurately detect.

In conclusion, the Coriolis Mass Flowmeter is a highly advanced and reliable instrument for measuring fluid mass flow.

Its unique operating principle, high accuracy, wide fluid compatibility, and multi-parameter measurement capabilities make it an invaluable tool in a wide range of industries.

As technology continues to advance, these flowmeters are likely to become even more accurate, versatile, and cost-effective, further expanding their applications in the world of fluid measurement and process control.