In industrial production, environmental monitoring, water conservancy and other fields, liquid level measurement is a key link to ensure the stable operation of the system. Traditional contact type liquid level measuring instruments (such as float type and differential pressure type) often face problems such as medium corrosion, blockage, and wear, while MEJ-MP ultrasonic liquid level transmitters have become an ideal solution for modern liquid level monitoring due to their advantages of non-contact measurement, intelligent algorithms, and strong anti-interference ability. This article will delve into its working principle, core characteristics, and application scenarios, showcasing its outstanding performance in complex working conditions.

Characteristics

Measure range: 0 ~ 10m

Blind zone: 0.35m

Accuracy: 0.5%F.S

Power supply: (18~28) VDC

With backlight

- Working principle of MEJ-MP ultrasonic liquid level transmitter: precise "time travel" of sound waves

- MEJ-MP Ultrasonic Level Transmitter Core Features: Comprehensive Upgrade of Industrial Grade Performance

- Typical application scenarios of MEJ-MP ultrasonic liquid level transmitter

- Selection and usage suggestions for MEJ-MP ultrasonic liquid level transmitter

- Component workshop

- Calibration workshop

- Product verification

- Fill out the form below to learn more

In industrial production, environmental monitoring, water conservancy and other fields, liquid level measurement is a key link to ensure the stable operation of the system. Traditional contact type liquid level measuring instruments (such as float type and differential pressure type) often face problems such as medium corrosion, blockage, and wear, while MEJ-MP ultrasonic liquid level transmitters have become an ideal solution for modern liquid level monitoring due to their advantages of non-contact measurement, intelligent algorithms, and strong anti-interference ability. This article will delve into its working principle, core characteristics, and application scenarios, showcasing its outstanding performance in complex working conditions.

Working principle of MEJ-MP ultrasonic liquid level transmitter: precise “time travel” of sound waves

The MEJ-MP ultrasonic liquid level transmitter works based on the principle of ultrasonic echo ranging, and the core process is as follows:

Acoustic emission: The probe (transducer) of the transmitter emits ultrasonic pulses towards the liquid surface, and the sound waves propagate in the air at a fixed speed (related to the temperature of the medium).

Echo reception: Ultrasonic waves reflect off the liquid surface to form echoes, which are received by the same probe.

Time calculation: By measuring the time difference Δ t between the emitted and received pulses, combined with the propagation speed v of sound waves in air, the distance D between the probe and the liquid surface is calculated

D= (v×Δt)/2

Liquid level conversion: Given the installation height H of the probe (the vertical distance from the measurement reference plane to the probe), the actual liquid level L is:

L=H−D

Key technical points:

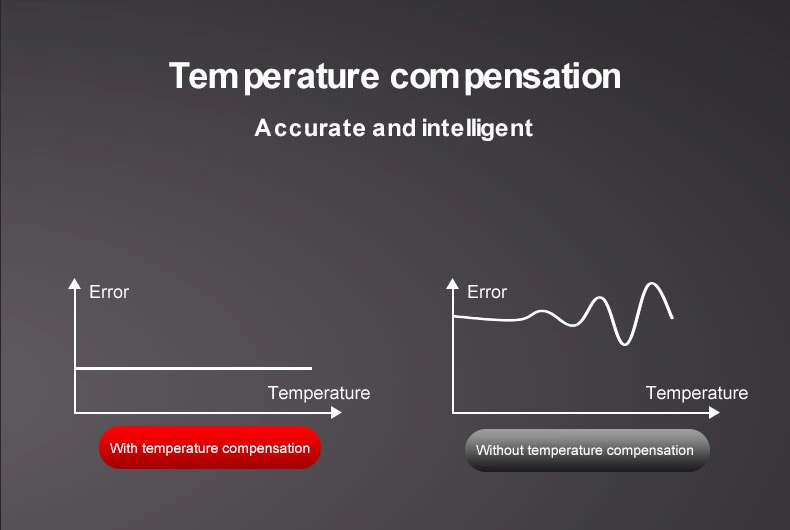

The built-in temperature sensor compensates for real-time sound wave velocity (v is proportional to temperature) to ensure measurement accuracy.

Intelligent echo processing algorithm is used to filter interference signals (such as obstacles in the container, foam, fog, etc.), and accurately identify the real liquid level echo.

MEJ-MP Ultrasonic Level Transmitter Core Features: Comprehensive Upgrade of Industrial Grade Performance

Non contact measurement, suitable for harsh working conditions

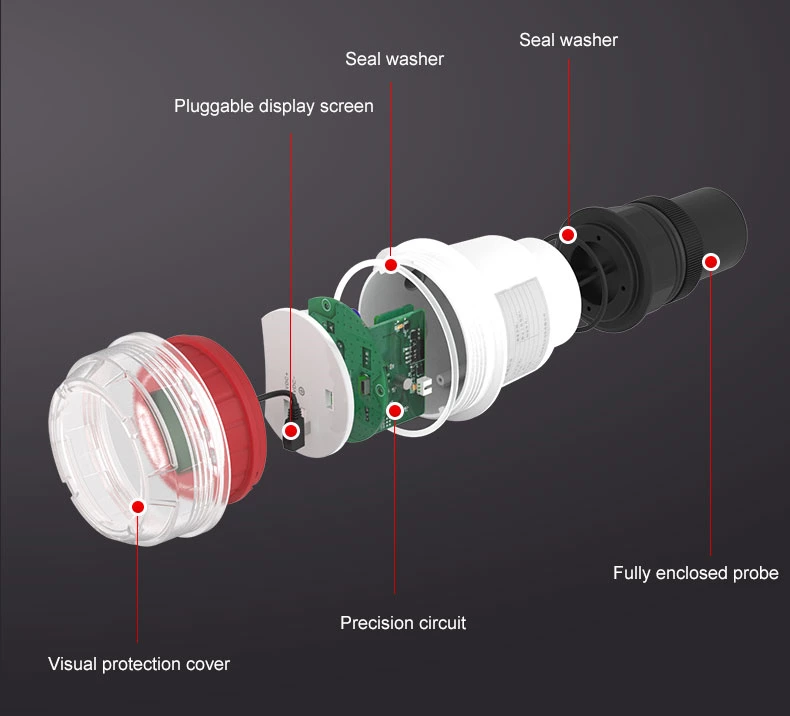

Non contact medium: The probe has no direct contact with the measured liquid, completely solving the corrosion, adhesion, and wear problems of traditional contact instruments. It is suitable for harsh environments such as strong acids, strong alkalis, high temperatures, viscosity, and easy crystallization (such as chemical storage tanks, sewage treatment tanks, and high-temperature water tanks).

Strong anti-interference design:

The probe adopts anti condensation coating and sealing technology to avoid the influence of water vapor condensation on sound wave emission;

Wide beam angle (6 ° -15 °, depending on the model) reduces container wall reflection interference and supports measurement of irregular containers such as elliptical and spherical tanks.

High precision and high stability

Measurement range: Conventional models cover 0.2-15m, while some high-end models can reach 30m, meeting the needs of containers with different volumes.

Accuracy level: ± 0.2% FS (full-scale error), repeatability error ≤ ± 2mm, superior to most similar products.

Long term stability: Built in digital filtering algorithm to suppress environmental noise (such as fan vibration and electromagnetic interference), ensuring data fluctuations are less than ± 0.1% per year.

Intelligence and multifunctional integration

Dual row LCD display: Real time display of liquid level value, distance value, temperature value, and working status (such as echo intensity, fault code), supporting switching between Chinese and English.

Multiple output modes:

Standard analog signal: 4-20mA DC (two-wire system) or 0-5V/0-10V DC (three wire system);

Digital Communication: Supports HART protocol, Modbus RTU (RS485 interface), compatible with PLC, DCS systems, and IoT platforms.

Intelligent diagnostic function:

Automatically detect probe contamination, line faults, signal blind spots (such as empty/full tanks), and output alarm signals;

Support historical data storage (such as the last 50 fault records) for easy fault tracing and maintenance.

Convenient installation and maintenance free

Flexible installation method: supports threaded installation (DN50/DN80), flange installation (DN100 and above), top or side installation, and adapts to different container structures.

Calibration free design: Full range calibration has been completed before leaving the factory, and there is no need for manual debugging after on-site installation. It can work when powered on.

Low power operation: The two-wire model has a power consumption of ≤ 1.5W and is suitable for outdoor scenarios powered by batteries or solar energy, such as reservoirs and oil storage tanks.

Typical application scenarios of MEJ-MP ultrasonic liquid level transmitter

Chemical and petroleum industries

Scenario: Corrosive liquid (such as sulfuric acid, caustic soda) storage tanks, crude oil storage tanks, and reactor level monitoring.

Advantages: non-contact measurement avoids medium corrosion probe, and intelligent echo algorithm penetrates a small amount of foam to ensure safe measurement in flammable and explosive environments (explosion-proof type is optional, and ATEX/IECEx certification is passed).

Sewage treatment and environmental protection field

Scenario: Measurement of liquid levels in sewage tanks, aeration tanks, and sludge tanks, monitoring of wastewater discharge flow (in conjunction with open channel flow meters).

Advantages: Resistant to water vapor and dust interference, the probe surface is smooth and not easily adhered to impurities, reducing maintenance frequency; Support liquid level flow conversion and real-time monitoring of sewage load.

Water conservancy and water engineering

Scenario: Reservoir water level monitoring, urban water supply tank level control, drainage pump station collection well level warning.

Advantages: Wide range coverage (up to 30m), adaptable to large fluctuations in high and low water levels; Support remote wireless transmission (with GPRS module) to achieve real-time data feedback from unmanned stations.

Food and pharmaceutical industry

Scenario: Measurement of liquid level in sterile tanks (such as milk storage tanks and liquid medicine storage tanks), and control of liquid level in food processing tanks.

Advantages: The probe material complies with FDA certification (such as 316L stainless steel+PTFE coating), meeting hygiene requirements; Non contact measurement avoids contamination risks and complies with GMP standards.

Selection and usage suggestions for MEJ-MP ultrasonic liquid level transmitter

Confirmation of key parameters

Measurement range: Select the appropriate range based on the height of the container, with a 10% -20% safety margin reserved (for example, if the container is 10m high, choose a 12m range model).

Medium characteristics:

Volatile liquids (such as alcohol and gasoline) need to consider the scattering of sound waves by steam, and wavelet beam angle models can be selected;

High temperature environments (>80 ℃) require the use of heat dissipation flanges or high-temperature probes (with a temperature resistance of up to 150 ℃).

Installation environment:

Regularly clean the surface of the probe in environments with strong dust (such as grain silos);

Outdoor installation requires the installation of a sunshade to prevent temperature drift caused by direct sunlight.

Installation precautions

Avoid interference sources: There should be no obstacles such as agitators or pipeline interfaces directly below the probe, and the distance from the container wall should be ≥ 0.3m (small range models) or ≥ 1m (large range models) to reduce reflection interference.

Temperature compensation setting: If there is a significant difference between the medium temperature and the ambient temperature (such as in cold storage or high-temperature furnaces), manual input of the medium temperature or an external temperature sensor is required for compensation.

Lightning protection measures: It is recommended to install lightning arresters outdoors to prevent damage to electronic components caused by lightning strikes.

Maintenance and troubleshooting

Regular cleaning: Wipe the surface of the probe with a soft cloth every 3-6 months to remove dust and water vapor condensation (do not use corrosive solvents).

Common troubleshooting:

No signal output: Check if the power wiring and fuse are blown, and confirm that the probe is connected to the transmitter host normally;

Large fluctuations in measurement values: Check whether there is severe stirring, bubble agitation, or echo intensity below the threshold in the container (adjust gain parameters or replace with a higher power probe).

| Product | Ultrasonic level transmitter |

| Model | MEJ-MP |

| Measure range | 5, 10m (others optional) |

| Blind zone | 0.35m |

| Accuracy | ±0.5%FS |

| Display | LCD |

| Output (optional) | 4-20mA RL<500Ω |

| RS485 | |

| 2 relays | |

| Measuring variable | Level/Distance |

| Power supply | (18-28) VDC (others optional) |

| Power consumption | <1.5W |

| Protection degree | IP65(others optional) |

Component workshop

Calibration workshop

Product verification